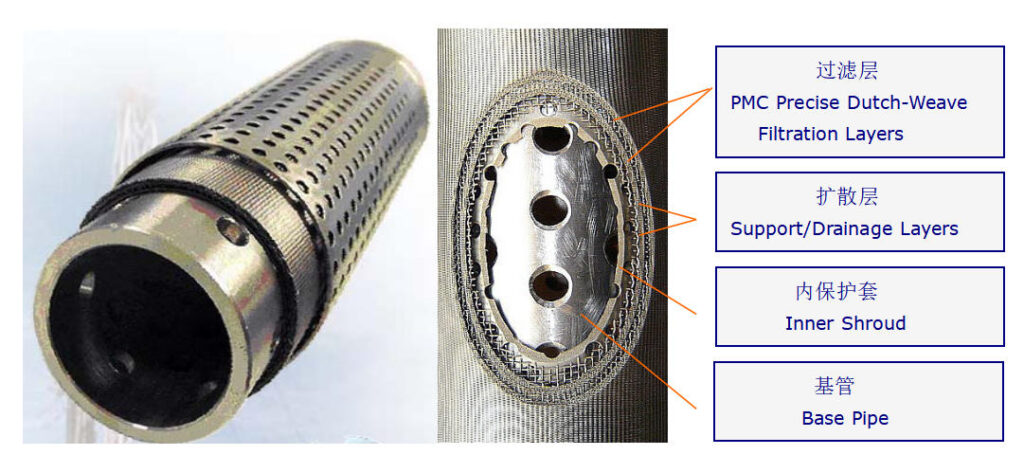

It is composed of a base pipe, a composite sand control filter sleeve, a stainless steel outer protective sleeve, etc. from inside to outside. The base pipe adopts API standard oil casing, and the anti sand filter sleeve is made of stainless steel precision microporous composite filter material, using a fully welded structure.

The composite sand control filter sleeve has the characteristics of high permeability, high strength, high deformation resistance, high reliability, and good corrosion resistance, making it an efficient product for mechanical sand control. The composite sand control filter sleeve consists of a base pipe, an inner protective sleeve, an inner support drainage screen, a filter screen, an intermediate support drainage screen, a dense mesh filter screen, and an outer protective sleeve from the inside to the outside. The form of the filter screen, sand control accuracy, and number of layers are selected according to the needs of the formation. The middle support drainage net provides uniform flow distribution for the lower layer of media, while also separating the upper and lower filter mesh to ensure filtration accuracy. The inner and outer protective covers can protect the drainage network and the medium layer; The overcurrent holes of the inner protective cover are uniformly distributed small circular holes, while the overcurrent holes of the outer protective cover can be uniformly distributed circular holes or bridge punching holes.

Product Features:

1. Adopting multi-layer 316L stainless steel precision microporous composite sand control filter layer, the sand control reliability is high and the anti damage ability is strong.

2. The filtration area is large, which is 10 times that of slotted and wound screen pipes, with low flow resistance and high yield.

3. The filter hole is stable and has strong resistance to deformation. When the radial deformation reaches 40%, the sand control ability remains unchanged, meeting the requirements for horizontal well use.

4. The filter holes are uniform, the permeability is high, the anti blocking ability is strong, the blocking cycle is 2-3 times that of ordinary sieve tubes, and it is easy to backwash.

5. Has good anti-corrosion performance

1) For general requirements, the base pipe adopts API standard casing oil pipe, made of steel grades such as J55 and N80, and the sand control filter sleeve and outer protective sleeve are made of high-quality stainless steel materials.

2) For the special requirements of wells containing H2S, CO2, and high Cl -, corrosion-resistant casing or tubing is used for the base pipe, and even stainless steel pipes are used. The sand control filter sleeve and outer protective sleeve are both made of high-quality stainless steel.